Carbon Neutral Initiatives

November 13, 2025

Elysis announces breakthrough in its low-carbon production technology

Written by Greg Wittbecker

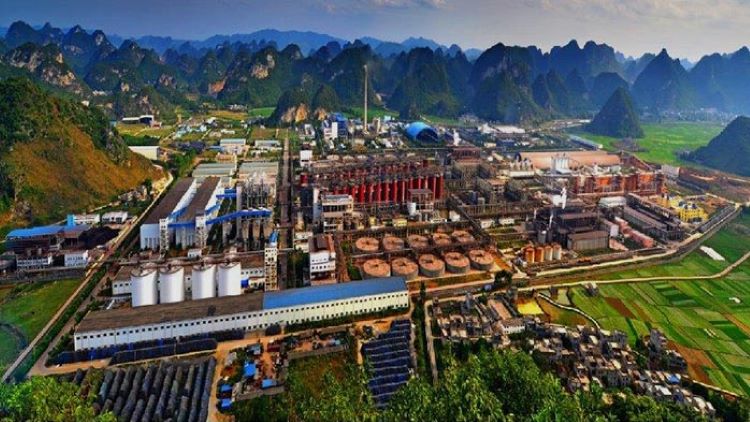

Elysis announced the start-up of its new technology at a Rio Tinto smelter, which it said is the next step in the transition toward large-scale, low-carbon aluminum production.

Elysis, a Montréal, Canada-based partnership between Alcoa and Rio Tinto, developed a 450 kiloampere designed inert anode cell, which has been deployed at the end of an existing potline at the Rio Tinto’s smelter in Alma, Québec.

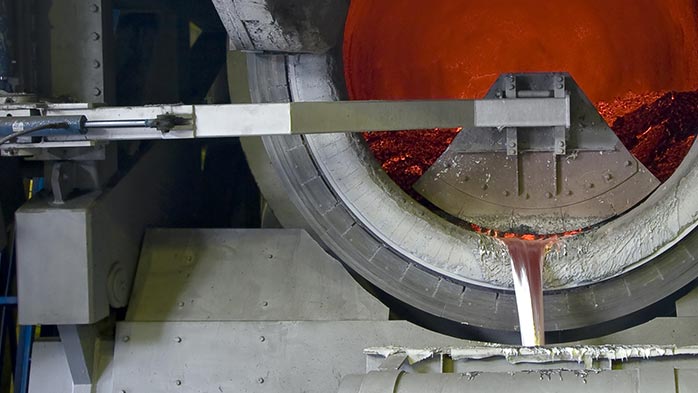

This news represents a breakthrough for the venture, as the 450ka cell is the first serious commercial scale pot that has been energized.

Why this matters

This is an important day for the Elysis joint venture. After decades of painstaking research at lab scale, the first serious commercial scale pot is now operating.

Up to now, Elysis has raised more questions than answers. Prospective clients are intrigued by the possibility of zero carbon smelting, and a process advertised as actually emitting oxygen. The elimination of conventional carbon anodes affords substantial savings.

However, the big unknowns are in energy consumption, longevity of the inert anode, and what it will cost to install the cell at scale.

The partners are able to start extracting data to begin addressing these burning questions.

We expect this single cell will run for an extended period before the next stagegate, which will be the addition of multiple pots to gauge performance in series.

These combined efforts start to build the necessary data to launch a viable commercial selling campaign for the technology.