Building & Construction

December 5, 2025

Hoover enters aluminum cladding with acquisition of Arconic asset

Written by Nicholas Bell

Hoover Treated Wood Products Inc. has purchased Arconic Architectural Products LLC, the Eastman, Ga.-based manufacturer of aluminum cladding.

The transaction moves Hoover into an exterior-material category it has not participated in before and establishes a new division – Hoover Architectural Solutions.

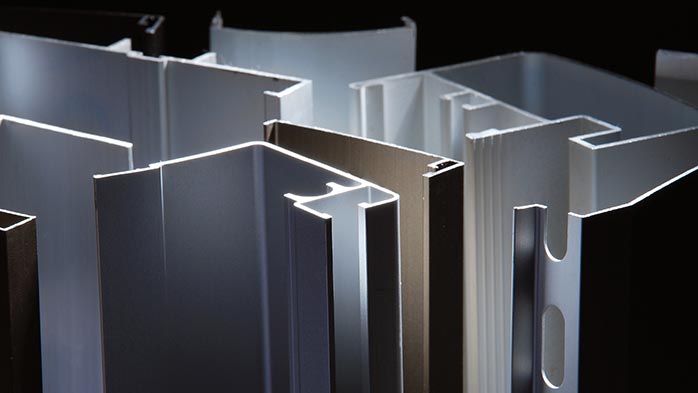

Through Hoover Architectural Solutions, the company will produce aluminum composite material (ACM) panels and related exterior products.

In this transaction, AAP LLC refers to Arconic’s North American cladding operation, while AAP SAS represents the separate European arm that is not part of the sale.

Eastman facility and product line

The Eastman site will manufacture Reynobond Fire Retardant and Reynobond Polyethylene panels, while also supplying Reynoplate and Reynoclad. Together, these products position Hoover to serve exterior cladding and signage markets throughout the US and Canada.

The press release did not specify whether the facility will continue to produce the company’s Reynolux-branded products as well

The architectural products associated with the cladding and signage end market are generally manufactured from 3000-series and 5000-series aluminum, and AAP has historically utilized 3005 alloy aluminum in many of their “Reyno”-branded products.

Business units and future plans

Hoover Treated Wood Products and Hoover Architectural Solutions will continue to operate as separate entities, though the acquisition signals a notable shift for the parent company as it moves from an exclusive focus on treated wood toward a wider mix of materials.

At the same time, the retention of Kawneer’s building-system manufacturing assets under Arconic suggests that while Hoover gains ground in ACM panel cladding, the broader façade-system business continues through existing channels.

Those existing channels would also likely include coated sheet supplied from the Merxheim, France, facility operated by AAP LLC’s former sister company, AAP SAS. That site is a global source of pre-painted aluminum coil and has also served as an internal supplier for the Reynolux aluminum used in some of AAP’s ACM panels.

Sebastien Jacob, now general manager of Hoover Architectural Solutions, said in the public announcement that the company plans to invest in the site so it can handle expanded production requirements over time.

Code requirements and safety standards

Hoover stated that the existing approach to code compliance and customer support will guide production as the new division scales while also noting in their company boilerplate that they maintain compliance with International Building Code (IBC) provisions.

One regulatory reason for this requirement is that many ACM and insulated-metal panel (IMP) wall assemblies include combustible components, such as polymer cores or foam insulation, which require increasingly stringent fire safety standards.

The International Building Code (IBC) serves as the overarching regulatory framework for exterior wall assemblies, while referring to National Fire Protection Association’s (NFPA) standard numerical designation 285 as the required fire-propagation test method for assemblies that contain combustible components, according to the North American Modern Building Alliance.

NFPA 285 and the IBC

The standard test used in the US is the NFPA 285, which assesses vertical and lateral flame spread in full-scale exterior wall assemblies.

The governing code for commercial building construction, the IBC, sets requirements for assemblies containing combustible cladding or insulation.

Under IBC provisions, exterior walls that include combustible components, including foam insulation, ACM cladding, or combustible water-resistive barriers, often must satisfy NFPA testing when used on buildings of certain construction types and heights.

Market context

By acquiring Arconic’s cladding operations and launching Hoover Architectural solutions, Hoover enters the exterior cladding market at a moment when fire-safety regulation and scrutiny are especially high. That may appeal to those specifying cladding for code-sensitive projects.

The move gives Hoover a direct path into a material category it has not produced before, since it can work with a platform that already meets the fire-testing and code-compliance requirements of the IBC and NFPA 285.