Global Trade

January 26, 2026

SDI says its big bet on aluminum is already paying off at ADI

Written by Stephanie Ritenbaugh

Steel Dynamics Inc. (SDI) leaned into its aluminum operations during its fourth quarter earnings call on Monday, touting progress at its flat-rolled mill in Columbus, Miss. – and hinting at future expansions in aluminum.

“There’s absolutely no doubt that aluminum will be a growth platform for us going forward,” said Mark Millett, co-founder, chairman, and CEO of the Fort Wayne, Ind.-based steel and aluminum maker. “There’s a lot of supply-demand dislocation, so there’s certainly phenomenal opportunities there for us.”

Millet made the comments during an earnings conference call with analysts on Monday. He also noted that expansion in aluminum would not preclude continued expansion in steel and other markets.

Key figures

SDI, which runs Aluminum Dynamics Inc. (ADI), has been ramping up production in Columbus, and at a recycled slab center in San Luis Potosi, Mexico.

The company reported $157.7 million in external net sales for aluminum in Q4’25, compared to $60.1 million in Q4’24. Full-year external net sales for aluminum reached $361.1 million, up from $258.5 million in 2024. All told, SDI reported $1.4 billion in cash flow from operations during the year, after investing $450 million in gross working capital in aluminum.

ADI shipped 10,000 tons in December, about 20% of its eventual capability. It expects to exit 2026 at a rate approaching 90% capacity.

Good timing

The timing of ADI’s mill has been fortuitous. Recent years have revealed knots in the supply chain, from Covid-19 upending logistics to the outage at Novelis’ aluminum mill in Oswego, N.Y., which is a major supplier to the automotive industry.

Millett estimated that the US has a domestic supply deficit of more than 1.4 million tons when it comes to aluminum sheet. Also, aluminum imports face a 50% Section 232 tariffs. That includes imports from Canada, which is by far the biggest source of foreign aluminum for the US market.

And ADI might not have to search too hard for customers. Millett said about two-thirds of SDI’s existing carbon flat-rolled steel customers also use aluminum flat-rolled sheet.

As far as operations go, ADI’s cast houses and hot strip mill are running “extremely well,” Millett said.

Key details

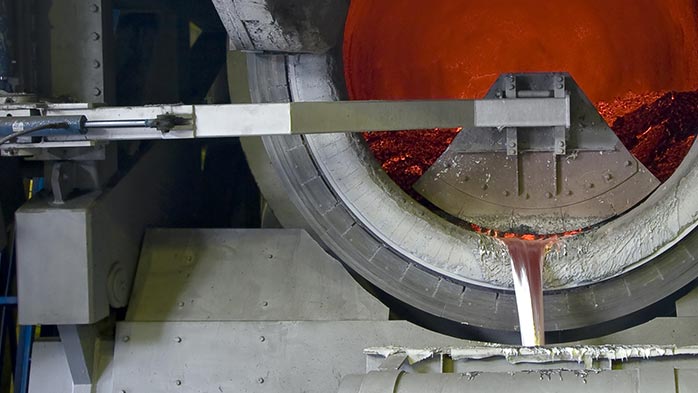

Three of the four melt cast houses are fully commissioned and have produced all 3,000, 5,000 and 6,000 series ingots for the industrial, can sheet, and automotive sectors, the company said. Notably, the hot mill has run 3003, 5052 industrial, 3104 can sheet, 5754, and 5182 automotive-grade material. The cold reversing mill is producing 3003, 5052, and 3104.

Commissioning is ongoing in other areas of the facility. And the company continues to receive key product qualifications.

ADI has in addition produced and shipped aluminum hot band for use in automotive applications. “We continue commissioning the cold mill and other downstream operations, including the CASH (continuous annealing and solution heat treatment) line. It is an extremely exciting time for all of us,” Millett said.

The first tandem mill is in commissioning and starting to produce. The second tandem cold mill and the first of two CASH lines are on schedule to be operating before the end of Q1’26.