Carbon Neutral Initiatives

July 1, 2025

Aluminum gets smarter: Filtration, coatings, and what comes next

Written by Gabriella Vagnini

It’s not just about making more aluminum anymore. It’s about making it better. Smarter. Cleaner. And if some of the latest tech developments are any sign, we’re at the front end of a whole new chapter in how aluminum is produced, used, and recycled.

Filtration that recovers aluminum before it’s lost

MIT researchers recently developed a nanofiltration membrane that can pull aluminum ions out of industrial wastewater, with more than 99% efficiency. This isn’t lab theory. It’s built to withstand the kind of harsh, acidic conditions you’d find in real plants. They tested it using cryolite-rich runoff and captured nearly all the aluminum that would normally be flushed away.

Think about what that means. Every year, thousands of tons of aluminum get lost in waste streams. This kind of recovery system doesn’t just clean up the mess, it turns a loss into a revenue stream. You’re no longer just producing aluminum. You’re recapturing it, looping it back in, and saving serious money along the way.

One of the researchers said it plainly: “We were able to capture 99.5% of the aluminum ions.” And they’re already talking about scaling it up into modules that could fit right into an industrial filtration setup.

So here’s the question for the industry, are we going to wait until regulations force our hand, or do we move now while this gives us a competitive edge?

Coatings that do more than just protect

On the other side of the innovation front is coating technology. Not the same old corrosion protection we’ve seen for decades. We’re talking smart coatings. Materials that can react to temperature, pressure, even surface damage. Think anti-icing skins for aircraft. Or coatings that send alerts when stress or fatigue shows up before it becomes a failure.

Some new systems even have self-healing capabilities, microscopic layers that close up small cracks on their own. That’s not just interesting science. That’s downtime avoided. That’s longer asset life. That’s real operational savings.

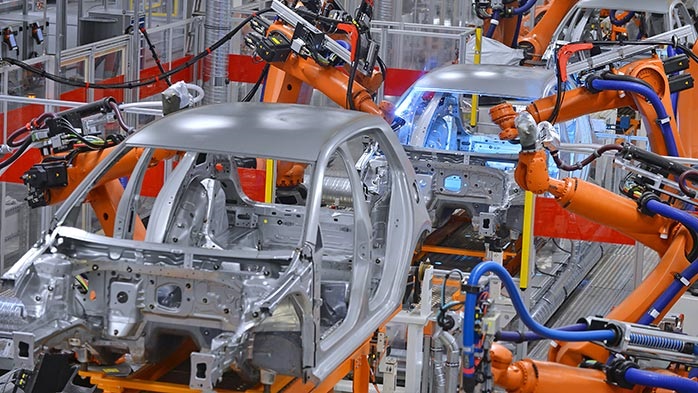

And from a market standpoint, these coatings aren’t just being talked about in research circles. Companies in aerospace, automotive, and defense are testing them in the field. Quietly, but seriously.

What this really means for aluminum

Put the two together, smarter recovery and smarter surfaces, and aluminum starts to look like something much more advanced than the commodity metal most people think of. If we can recover metal from waste, embed intelligence into surfaces, and extend lifecycle all at once, the entire value chain starts to shift.

You’ve got tighter circularity. Lower production costs. Stronger sustainability metrics. Less risk from labor shortages or maintenance surprises. And in a world where everyone’s watching emissions, energy use, and material waste, that’s no small thing.

Final thought

Aluminum has always been lightweight and endlessly recyclable. But now, it’s becoming something else, intelligent. The next real edge isn’t in capacity or price. It’s in how smart your metal is. The industry needs to ask: Are we investing in that now, or are we going to let the rest of the world pass us by?