Aluminum Scrap Markets

February 12, 2025

The quiet giant: A new force in aluminum is taking shape

Written by Gabriella Vagnini

(This conversation with ADI took place on February 6, 2025.)

Aluminum is quietly undergoing a shake-up, and ADI is right at the center of it. Backed by Steel Dynamics (SDI), ADI is gearing up to make a serious impact, just like SDI did with steel. With new capacity coming online, shifting trade policies, and a supply chain in flux, ADI’s next moves could change the game for North America’s aluminum market.

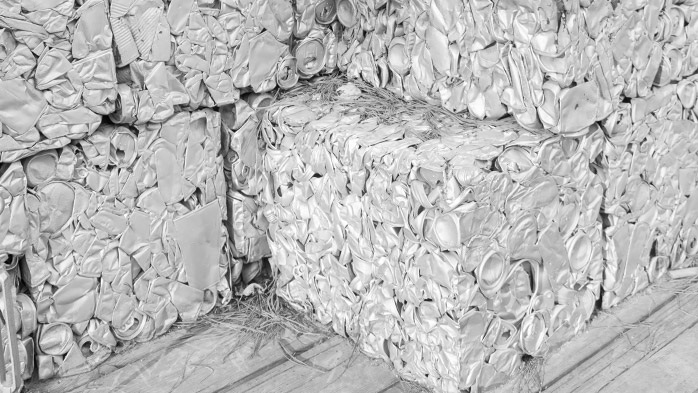

Scrap supply and market positioning

With two major mills coming online and a growing appetite for scrap, ADI sees itself in a strong position. “This is good news for us,” they said, emphasizing their ability to secure material. Scrap sourcing can be unpredictable, but ADI’s partnerships, especially in Mexico, are helping them stay ahead of the curve.

Mexico’s tax and duty structures can make aluminum procurement tricky, but ADI has found ways to work within the system by partnering with local traders. “We have to commit early to keep the material flowing,” they explained. With their new scrap-fed facility set to commission by late March, securing feedstock ahead of time has been a top priority.

Trade, tariffs, and the Mexican slab question

Trade policy remains a wildcard for ADI, particularly when it comes to rolling slab imports from Mexico. “Since we’re rolling slab from a different facility, we have to go through the Department of Commerce process,” they said. That means proving that domestic casting capacity isn’t enough to meet demand, a process that can be both long and complex.

There’s also a lot of uncertainty about how trade policies will be handled moving forward. “No one knows if the manpower or the exclusion process will stay the same,” they admitted. ADI is watching closely for any opportunities to navigate these changes.

One possible solution? Foreign trade zones (FTZs). ADI mentioned a potential tariff exemption for imported materials processed within an FTZ, but it’s still unclear whether it will apply to their operations. If it does, it could give them a major cost advantage.

Midwest premium spike and market trends

Since January 31, the Midwest premium has surged nearly 20%, a jump that ADI has been closely tracking. “It went from $25.25 to $28.20 in just three days, which is ridiculous because the supply crunch hasn’t even happened yet,” they pointed out.

This price spike is being driven by inflation, market speculation, and supply concerns, but ADI expects a correction in the near future.

At the same time, North America is solidifying its position as an aluminum powerhouse. Right now, 80% of the primary aluminum consumed in the U.S. comes from Canada, with significant volumes also coming from Mexico and Arizona. With more domestic capacity ramping up, the U.S. is becoming less dependent on overseas imports—a shift ADI is looking to capitalize on.

Kloeckner partnership: expanding downstream capabilities

Beyond its backing from SDI, ADI is also strengthening its downstream reach through a growing partnership with Kloeckner. “You’re basically doing everything in-house” I asked, referencing their increasing integration. Kloeckner will be co-locating operations at ADI’s north campus, handling downstream processing right on-site. This move eliminates logistical headaches and improves efficiency, keeping ADI streamlined and cost competitive.

Logistics is another big advantage for ADI. “Being on rail is huge,” they said, pointing to cost savings and a more reliable supply chain. Many aluminum producers struggle with transportation bottlenecks, but ADI’s proximity to rail lines and key transport hubs gives them a clear leg up.

What keeps ADI up at night?

I asked ADI’s leadership what concerns them most, and they didn’t hesitate—market uncertainty, shifting regulations, supply chain challenges, and the long qualification process for major customers. “A lot can happen,” they acknowledged. While new domestic capacity is ramping up, major buyers, especially in automotive and aerospace, take time to qualify suppliers. Even with the right material and infrastructure, securing long-term customer contracts is a process that doesn’t happen overnight.

Still, ADI is confident in its trajectory. By 2026, they expect to be producing 650,000 metric tons (1.43 billion lbs) of aluminum products. Their mix? 34% can sheet, 33% automotive (5000-6000 series), and 31-32% industrial alloys.

How ADI’s growth impacts the industry

ADI’s rise isn’t happening in a vacuum, it’s shaking up the entire aluminum industry.

✅ Domestic production over imports – more domestic supply means less reliance on overseas sources, reducing import demand.

✅ Scrap market tightening – with ADI consuming massive amounts of scrap, competition for feedstock will heat up, potentially driving up prices.

✅ Trade & tariff adjustments – if tariffs and trade policies keep shifting, companies like ADI will need to stay flexible, finding ways to work within evolving regulations.

✅ Pressure on traditional producers – ADI isn’t just another mill, it’s backed by Steel Dynamics, a company known for efficiency, cost control, and aggressive growth. This puts pressure on established players like Alcoa, Novelis, and Kaiser Aluminum.

✅ More supplier options for auto & packaging – ADI’s entry gives automakers, and beverage can producers another domestic source, potentially leading to pricing shifts and new contract opportunities.

Bottom line

ADI isn’t just another aluminum supplier, it’s a company with serious backing, smart partnerships, and a supply strategy built for long-term success. With a disciplined approach to scrap sourcing, a sharp eye on trade policy, and a logistics network designed to keep costs low, ADI is setting itself up to be a dominant force in the industry.

There are still a lot of unknowns in the market, but one thing is clear, when ADI is fully online, it’s going to shift the aluminum landscape just like SDI did with steel.