Carbon Neutral Initiatives

April 28, 2025

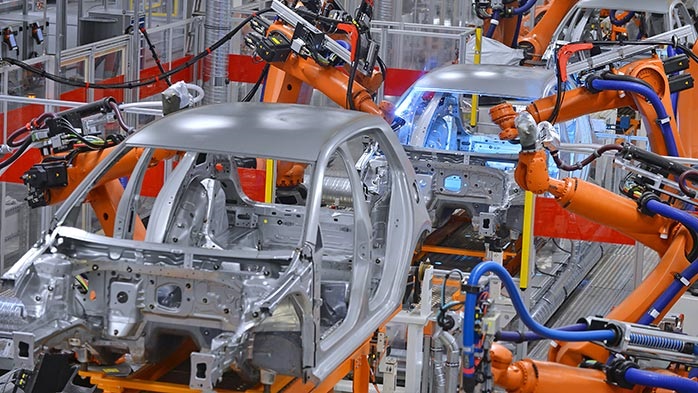

Cross-border castings: Hydro and Nemak rethink scrap to power low-carbon cars

Written by Nicholas Bell

Casting a new mold

Aluminum producer Norsk Hydro and automotive casting manufacturer Nemak signed a letter-of-intent (LOI) to collaborate on developing low-carbon aluminum castings for automotive applications.

The agreement’s focuses on expanding the use of post-consumer scrap and shifting to lower-carbon energy sources, such as natural gas and electrical boilers, like the methods used at Hydro’s Alunorte alumina refinery in Brazil. Hydro’s Alumetal subsidiary – fully acquired in 2023 – will also contribute to the process by supplying post-consumer scrap for new alloy production.

The partnership aims to qualify new foundry alloys for automotive applications, potentially influencing regional production of low-carbon aluminum grades. Hydro and Nemak share a target of achieving net-zero aluminum solutions by 2050 or earlier.

One notable detail of the LOI is the prioritization of post-consumer scrap. Hydro has two facilities based in Mexico, but their primary product line is aluminum tubing: albeit for the automotive industry as well as the HVAC sector. Hydro tangentially has 24 extrusions plants, recycling facilities, and fabrication centres in the US. Conversely, Nemak has eight manufacturing locations in Mexico and an additional four in the US…. As well as a facility in Poland.

Borderline advantage: Why Mexico matters

The agreement highlights a broader strategy of safeguarding decarbonization requirements by automotive manufacturers and UCMCA compliance for both companies. Although Alurnorte is not North American, alumina produced there supplies Hydro’s primary smelters, helping meet automaker demand for traceability of carbon emissions, especially with low-carbon aluminum being exempt under Section 232 tariffs.

Alumetal’s role is also key. The Polish subsidiary processes post-consumer scrap that can be blended into Mexican-made parts without violating USCMA rules, provided it stays under the aluminum content threshold. This creates a new hedge against North American scrap shortages: throughout 2024, Poland was not a notable supplier of automotive-grade scrap into the US, aside from minor volumes of used beverage can scrap and recyclable containers, which typically is not used for casting alloys or structural automotive applications.

Nemak supplies the Big Three domestic auto manufacturers in the US, despite a large share of their operations being located just over the Mexican border. Meanwhile, Hydro’s new Cassopolis plant – designed to process post-consumer aluminum and produced its’ low-carbon CIRCAL product line – uses at least 75% recycled content.

Closed loops and open questions

The key question for the US aluminum market is how the collaboration will impact scrap flows. Will Mexico absorb more of US-generated post-consumer aluminum through a closed-loop recycling system with Hydro? Will Hydro’s recycling facilities absorb more Mexico-generated secondary prime cast scrap that’s not quite “post-consumer”, like the distinguishing factor between new cast and old cast?

Overall, the partnership strengthens USMCA-aligned, low-carbon supply chains as a sourcing option for domestic automotive manufacturers – though the reliance on inputs from Brazil and Poland underscores the complexity of how material flows meet regional content requirements.