Building & Construction

June 18, 2025

Parsing construction demand: What Oldcastle and Jeld-Wen closures reveal about the B & C market

Written by Nicholas Bell

The U.S. building and construction sector, a cornerstone for aluminum demand, is exhibiting signs of instability, despite the overall opaqueness of the end market.

One trend playing out across two companies – each representing a different subsector of the end market – underscores the kind of slow-moving tremors that often go unnoticed until a slowdown is already well underway.

Top-down approaches can often be hazy. Real-world company examples cut through the noise more effectively, especially in a market where its hard to say which companies are true bellwethers.

Why construction demand is hard to hammer down

The term “automotive demand” typically triggers thoughts of the “Big Three” or Japanese and European car companies. Maybe it evokes thoughts of OEMs further upstream representing a niche market – wheels, transmissions, chassis, etc. The point is you could probably name ten companies that are a proxy for automotive demand.

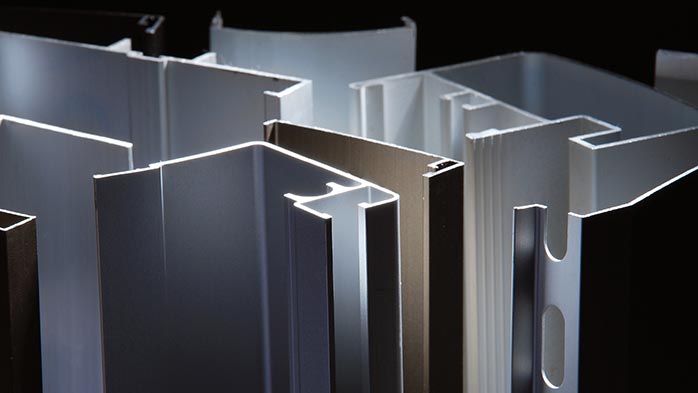

As it relates to the aluminum market, “automotive demand” further conjures up thoughts of secondary aluminum like A380.1 on the alloy side and old cast on the scrap side. And to be fair, when you look at it strictly through the aluminum lens, building and construction has its equivalents too: 6XXX-series extrusions, 3105 and painted siding scrap.

But what are the names that come to mind when someone says “building and construction demand”?

It’s hard to pinpoint and industry as fragmented as “B & C”.

Defining B & C demand in aluminum terms

Put in demand terms, the non-residential aluminum market represents the larger share of demand compared to residential. Taken as separate end uses, extrusions tend to be overwhelming across the non-residential construction footprint, for systems like curtain walls and façade systems. Rolled products show up in this space too, though to a lesser extent. Residential construction, on the other hand, tends to lean heavier on coil-based rolled goods and lighter-duty extrusions – namely rainware as well as window and door framing.

Most of these products, particularly in non-residential construction, are affixed to sites sometime after the structural framing and mechanical/electrical/plumbing (MEP) rough-in but before the interior fit-out (drywall, flooring, etc.).

Many of the companies operating in this space are just as – if not more – glass-oriented, given their focus on building envelope and window system solutions that often rely heavily on aluminum.

Non-residential Case Study: When the envelope folds

Recent plant closures by industry giant Oldcastle BuildingEnvelope, a leading fabricator and distributor of architectural aluminum and glass products, underscores that point.

Oldcastle has undergone a sweeping consolidation. The company just announced its intention to close its Midwest Glass Fabricators’ Highland, Michigan and Louisville, Kentucky facilities, only weeks after the decision to close its’ Hauppauge, New York facility. The company close its Los Angeles, California site just before the New Year, followed by Buffalo, New York facility a couple of months later.

The repeated wave of closures, especially of recently acquired assets in the case of Midwest Glass Fabricator’s two plants, suggests a recalibration tied to evolving market conditions or possibly internal efforts to streamline the business.

Cracks in the foundation

The broader non-residential construction landscape reinforces some of these concerns, as industry data suggests a stagnation in spending.

Total non-residential construction spending in April 2025, the most recently available data, increased by 2.8% year-over-year against a backdrop of 2.3% inflation over the same period.

One key caveat: spending on religious buildings, amusement facilities, and recreation centers drove most of the increase. Construction spending on religious buildings alone varies substantially. For instance, current spending pales in comparison to the money put towards religious construction in the early-to-mid 2000’s, despite two decades of inflation.

Amusement and recreation spending has skyrocketed over the past decade, as has wastewater infrastructure – neither of which directly correlate with aluminum demand.

It’s true that construction spending on office buildings increased year-over-year in April, despite a softening of the catchall “commercial” spending. The case could be made that this largely reflects higher input costs and delayed completions, but even if it didn’t there’s another issue facing the subsector.

Around 20% of commercial real estate debt securities, which would include “office” and “commercial” in this case, are maturing this year, according to the Mortgage Bankers Association. Moreover, vacancy rates are around the same 20% mark – exceeding the pre-pandemic averages by quite a few basis points.

More subdivisions than skylines

Residential real estate is far from a niche – single- and multi-family housing together account for around 30-40% of total aluminum demand from the building and construction sector. And unlike non-residential construction, rolled products account for the larger share of residential aluminum demand, compared to extrusions.

The signals are a little clearer and tend to come a little earlier than non-residential construction. While non-residential projects tend to be longer-cycle, residential starts and completions respond faster to shifts in interest rates, consumer sentiment, and material cost pressures.

Residential Case Study: A window into housing strain

Which brings about another case study in the architectural aluminum sphere.

Jeld-Wen, one of the largest window and door manufacturers focused mostly on the residential subsector, has announced their own spat of closures this year, most recently at its doors plant in Chiloquin, Oregon, following the shuttering of its Grinell, Iowa site at the top of the year. These follow a series of closures in 2024: Vista, California; Hawkins, Wisconsin; Wedowee, Alabama.

Jeld-Wen’s financial reports softening demand and rising input costs in its North American operations. The pullback is a telling indicator of slackening demand in mid-tier home renovation and new builds.

Cracks in the porch

Typically, residential construction spending precedes drops in non-residential construction, because the residential real estate market is more sensitive to economic changes and interest rates, a pattern that appears to be playing out given the 6-12 month lag of Oldcastle’s closures compared to Jeld-Wen’s.

That pressure is showing up in the numbers. Single-family housing starts have posted year-over-year declines every month of 2025 so far. Multifamily construction, while more resilient is beginning to soften as well. And in a curious twist, one metric is trending the opposite way: housing permits authorized but not yet started have increased nearly every month for the past year – suggesting builders are hesitating to break ground amid ongoing economic uncertainty.

Conclusion

Construction remains a critical pillar of aluminum demand, but it’s not a monolith. From large-scale curtain wall systems to residential window frames, the sector is fragmented, cyclical, and regional. Looking at aggregated top-down construction data can miss the nuanced demand shifts happening underneath the surface.

Plant closures at Oldcastle BuildingEnvelope and Jeld-Wen are two sides of the same coin: indicators of softening demand in different slices of construction.