Building & Construction

October 3, 2025

Looking for demand in all the wrong places

Written by Greg Wittbecker

The big question we are all trying to answer is: If and when will demand for aluminum take a hit as a result of the tariffs?

Naturally, we are watching the familiar macro data sets. Closer to home, monthly shipment data from the Aluminum Association is closely followed.

The problem with all this data is that it is historical, not forward-looking. Our best indicator of future demand is orders, and even that can be problematic. The way orders are tracked makes no recognition of the differences in timing when buyers place orders.

For example, if a major automaker decides to purchase all their aluminum for 2026 in October 2025, it shows up as a large order in October 2025. You get some “lumpy” front loading of orders without really understanding the timing of the actual shipments.

Ideally, we would love to have indicators that give us better clues about future demand. It may be time to go looking for them in all the wrong places.

Here are a few ideas…

Corrugated boxes and packaging

It is tempting to ask why we should care about corrugated packaging.

I would argue that packaging is critical in aluminum products. Corrugated material is used in our pack-and-ship processes. We also get our maintenance, repair, and operations (MRO) products in corrugated boxes.

Scrap generators, processors, and mill buyers are familiar with the ubiquitous “gaylord boxes” that handle thousands of tons of aluminum scrap into each year.

So, there is more corrugated in the front end of the supply chain than meets the eye.

At the other end of the consumer supply chain is the “Amazon effect.” That’s the weekly ritual when consumers recycle (hopefully) all those flattened cardboard boxes from the past week’s purchases.

This pattern is borne out by estimates that old corrugated containers (OCC) represent over 50% of the volume going through Material Recycling Facilities (MRF) in the US.

Intuitively, this suggests corrugated demand must be strong – and rising. However, industry experts say otherwise.

Some red flags about corrugated demand in 2025

Despite the “Amazon effect,” things are not so strong in corrugated and containerboard demand.

Industry analysts are sounding the alarm about major consolidation and plant closures. In 2025, 3.9 million short tons of capacity have been retired, representing 10% of total capacity.

The Wall Street Journal reported in its Sept. 21, edition per-capita shipments are down 20% from their 1999 peak.

The Fiber Box Association says US box shipments hit their lowest second-quarter levels since 2015.

Part of this demand destruction is due to more efficient packaging, as manufacturers design containers to do the same job but with less material. Material substitution is also a factor, with products such as plastic clamshells replacing traditional corrugated boxes.

The more worrisome concern is whether consumers are starting to curtail online shopping, which reached a frenzy during the Covid-19 pandemic.

Going forward, we will be monitoring:

- Further closures of corrugated capacity

- Amazon sales along with other major online retailers

- MRF-reported volume of OCC handled

- Guidance from listed corrugated fiberboard companies

All of these may be clues that the long-feared pullback in consumer spending has arrived.

Cement

Cement seems like an odd commodity to compare with aluminum, but it is worth tracking. Multiple sources forecast the US needs massive investment in infrastructure – topping $9 trillion. That level of investment will have substantial spillover effects on both steel and aluminum.

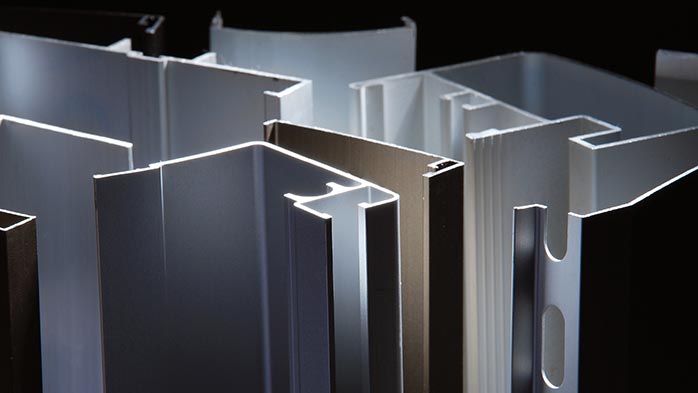

Cement is largely made to order; producers don’t build substantial inventories. Hence, cement shipments tend to reflect real demand. That real demand comes in the form of infrastructure, industrial, commercial, and residential consumption. Nothing gets built without a foundation of concrete. Extruded aluminum is widely used in industrial concrete molds designed for repeated use.

Cement isn’t just in the foundation, but also in cinder block, concrete block, and pipe. While we have not located credible, publicly-available data on this segment, estimates place the concrete block market at $12 billion-15 billion per year.

Once that foundation is laid, steel demand responds quickly for infrastructure, industrial, and commercial projects. Multi-family residential projects may employ steel, but single-family construction rarely does. Aluminum demand typically comes later in the construction cycle, such as extruded curtainwall in low- and high-rise projects.

Single-family construction yields aluminum demand in heating/cooling vents, gutters and downspouts, windows and doors, decorative trim, and white goods.

The point is that cement shipments are a useful gauge of aluminum extrusion and sheet/plate demand.

U.S. cement shipments down by 2% in June 2025

Total shipments of Portland and blended cement, including imports, were an estimated 9.16 million tons in June, a 2% decrease from 9.40 million tons a year ago, according to the latest US Geological Survey data.

Shipments for the first six months of 2025 reached 47 million tons, down by 5.3% year-on-year. The leading cement-consuming states were, in descending order: Texas, California, Florida, Ohio, and Illinois, which together accounted for 38% of total shipments in June.

These declines in cement correlate to the performance in aluminum extrusions (-1.5% year to date) and sheet/plate shipments (-1.7% year to date). Six months is not a long enough to establish a firm correlation, so we are backfilling shipment data for the past 5 years vs. cement to see if the relationship remains this high.

Still, the short-term correlation in 2025 could be an early warning that construction is slowing and taking a toll on aluminum demand.

Going forward, we will be monitoring

- US Geological Survey monthly reporting of cement shipments

- Available data on concrete block and pipe shipments

- Listed cement company guidance

Coatings

Painted and anodized extrusions are a standard part of every extruder’s catalogue. Painted sheet is a staple of building products, and high-performance coatings line every beverage can sold.

Detailed shipment data for coatings is only available by subscription from the American Coatings Association (ACA). However, we do have their 2025 forecast.

The ACA forecasts a 2.3% increase in coatings volume for the year, reaching 1.39 billion gallons.

Their estimate for individual market sectors was as follows:

Architectural coatings were expected to rise 2.3% in volume. This segment is especially important to the extrusion market, supplying curtainwall profiles for low- to high-rise construction.

Special-purpose coatings were forecast to grow 2.6% in volume. This segment covers the automotive refinishing market and industrial maintenance. The automotive market is naturally a large consumer of both extrusions and sheet.

The ACA also highlighted challenges facing the industry:

- Supply chain bottlenecks

- Specific pigments, additives, and raw materials remain tight, especially those coming from Europe. We are acutely aware this is a problem for extruders, who were already facing issues in 2023-2024 getting high-performance paint for curtainwall applications.

- Logistics and energy costs remain high

We reviewed the most recent guidance from Sherwin-Williams and PPG, two leaders in this sector.

PPG’s guidance:

- Second-quarter architectural coatings sales fell 4.85% year over year, with Europe very weak but partially offset by Mexico. Overall volumes was down by 2% over the same period.

- Performance coatings were up 3% on volume in the second quarter thanks to record aerospace (high single-digit growth). Their traffic solutions business (e.g., highway signage) was strong. Automotive refinishing benefited from market share gains, although collision claims declined. Highway signage is an important market for common-alloy sheet production from companies like Jupiter Aluminum and Vulcan.

- Industrial coatings were flat, as weaker automotive OEM demand was offset by stronger packaging demand from beverages.

Sherwin-Williams’ guidance:

- Performance coatings volume was flat-to-low single-digits

- Consumer product volumes are expected to be down by low single-digits

- Paint store product volumes are forecast for small low single-digit growth

- Economic guidance was cautious

- Fed interest rate cuts are now too late to influence demand

- The Leading Indicator of Remodeling Activity (LIRA), produced by the Harvard Joint Center for Housing Studies, points to very marginal growth heading into 2026 (only 1.2%-2.2% growth)

- Household debt is at record levels – $18.39 trillion – as of Q2’25.

Going forward, these are things we will be monitoring:

- Available ACA forecasts for 2026

- Listed coatings company guidance

Why this matters

We are indeed getting into the weeds when we start studying corrugated, cement, and coatings for clues on aluminum demand. But this level of detail is necessary, because the standard macroeconomic indicators are not giving us clear enough signals about whether demand is shifting.