Building & Construction

December 19, 2025

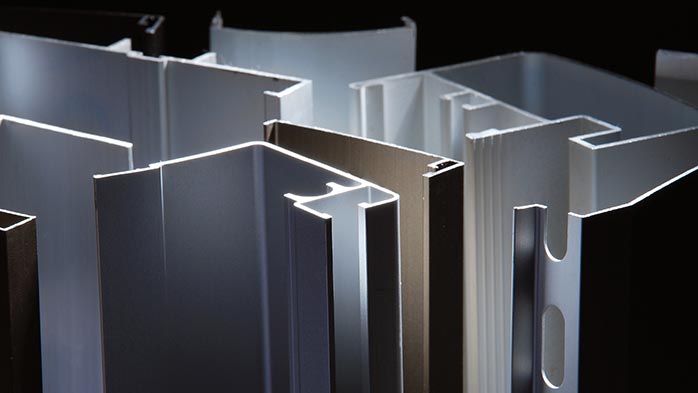

MMG Extrusions completes multi-year expansion at New Hampshire facility

Written by Nicholas Bell

Momentum Manufacturing Group’s (MMG) engineered extrusions unit has completed a multi-year expansion and automation project at its Franklin, NH, aluminum extrusion facility.

The project, which unfolded in phases between 2021 and 2025, increased capacity and added automated material handling and aging systems, according to a company press release.

The company said total investment exceeded $30 million and resulted in a doubling of annual production capacity, alongside expanded fabrication and logistics space.

Phase one

The first phase focused on extrusion capacity. MMG installed a 2,920-ton, 8-inch extrusion press supplied by Italy-based Presezzi Extrusion Group. The company commissioned the press in 2022 and said the line increased annual output to nearly 25,000 metric tons (t) of custom aluminum profiles.

The additional press allowed MMG to address higher demand for extruded profiles following the Covid pandemic, according to the Massachusetts-based company.

Company leadership linked that demand to both existing customers and new business tied to manufacturers relocating extrusion work to North America.

In parallel, MMG relocated and expanded its fabrication and machining operations into a nearby 50,000-square-foot building. That move separated downstream processing from press operations while increasing available floor space for secondary work.

Phase two

After completing the press installation, the company launched a second phase in 2022 that focused on automation and facility expansion. MMG invested an additional $11 million in infrastructure and automation technology, including a $6 million construction project.

That work added 35,000 square feet of manufacturing and logistics support space, increasing the total plant footprint to 150,000 square feet. The expansion also added six loading bays equipped with overhead cranes, which the company said improved trailer loading efficiency for finished extrusions.

Automated aging and material flow

The centerpiece of the second phase was a $5 million automated aging and packing system supplied by Belco Industries. The company said the system allows extrusion production and packaging to operate in a fully automated sequence from press exit through shipping.

The automated line connects aging, packing, and material movement into a single process rather than treating them as separate operations.

Added downstream processing capacity

The company also expanded downstream processing capability. MMG reported more than $5 million in additional investment in machining, fabrication, and assembly equipment, which included two automated 5-axis CNC machining centers intended for single-step processing of extruded aluminum components, a Trumpf 7000-series tube laser for tubular profiles, and equipment used for bending large-diameter extrusions.

Downstream growth

Looking ahead, MMG said it continues to evaluate further expansion opportunities, with attention directed toward additional downstream production capabilities such as robotic welding and bending.

The Franklin facility now combines expanded press capacity, automated material handling, and downstream processing under one operation, positioning MMG to support customers seeking integrated extrusion and fabrication services within North America.