Global Trade

January 29, 2026

Climbing prices, mill repairs, smelter expansions and more kick off January

Written by Stephanie Ritenbaugh

We’re barely into February, and a lot has already happened this year. Let’s dive in.

January began with news that the US had entered Venezuela and captured President Nicolás Maduro and his wife, Cilia. Fallout from the military operation included renewed discussions about the country’s resources. Against that backdrop, it is worth revisiting another of Venezuela’s commodities and its history in the global supply landscape — aluminum.

Consumers have now endured seven consecutive months of steady increases in the Midwest premium, rising from the high-50s in early June 2025. The question now is when – or whether – that appreciation slows or reverses.

Still, higher premiums have not sufficiently mobilized importers to direct more metal to the US. The latest data from the US International Trade Administration’s Aluminum Import Monitor helps explain why.

Novelis expects it will cost $255 million to repair damage to its rolling mill facility following major fires in Oswego, N.Y. It remains unclear how long the repairs will take, as a second fire in November damaged the hot mill’s finishing line, the company said in an application seeking financial assistance filed with the County of Oswego Industrial Development Agency. Novelis began repairs in September, estimating they would be completed in December at a cost of about $550 million–$650 million. However, the November blaze tore through the finishing mill, upending that plan.

Anheuser-Busch InBev (AB InBev) has exercised its option to repurchase the 49.9% minority stake in its US-based metal container plants from a consortium led by Apollo Global Management, completing a transaction valued at about $3 billion. The repurchase reverses a deal completed at the end of 2020, when AB InBev sold the same minority stake to support balance sheet deleveraging during the first year of the COVID-19 pandemic.

The fourth quarter is typically not a strong period for recreational vehicle shipments, as dealers reduce year-end inventories during the “winter dead zone” for RV sales. However, 2025 declines were steeper than usual, which may be an early sign that consumer discretionary spending is being constrained by the persistent effects of inflation.

Price action in aluminum, copper and steel has stirred new speculation about substitution impacting aluminum. This often happens when there is a blowout in prices, but it may be more intense this time given the recent stunning highs.

A number of collective bargaining agreements across aluminum producers – including Alcoa, Kaiser, Century, and Hydro – either expire this year or are entering bargaining cycles. As those timelines converge, 2026 may be a year in which labor negotiations play a larger role in operational planning, at a time when trade issues and high prices are also significant factors. AMU’s Nicholas Bell gets into the details.

Aerospace offers a useful reference point for aluminum market participants, even though it remains a smaller demand driver than automotive or construction. Aircraft production concentrates demand in 2000- and 7000-series alloys and their related scrap streams, where copper content matters more than in most other alloy groups. That matters during a period of elevated copper prices, which continue to affect alloys costs, substitution decisions and scrap values, as well as knock-on effects from climbing copper contracts on broader commodity settlements in terminal markets.

The US Department of Defense is taking a $150 million stake in Atlantic Alumina Company LLC (Atalco) to expand alumina production and establish gallium production, a critical component of satellite systems, semiconductors, energy technology and other military and aerospace applications. The investment is the latest example of the Trump administration investing directly in companies. A prime example in the metals industry is the “golden share” in Pittsburgh-based U.S. Steel Corp. as part of its purchase by Japan’s Nippon Steel.

November trade data showed China had already surpassed the prior year’s full-year total, with December continuing that trend. Increasingly, countries appear willing to tolerate higher Chinese imports in exchange for improved access to China’s market, rather than accept the volatility inherent in current US trade policy.

Commodities analyst Edward Meir shared his outlook for aluminum in 2026, offering his thoughts on tariffs, Century Aluminum’s restart of its Mt. Holly smelter, the Midwest premium and China’s production outlook.

Like the Midwest premium, the London Metal Exchange (LME) cash settlement is soaring as well. Cost-push inflation may require the LME to move higher—and stay higher—for longer in order to incentivize investment in primary capacity outside China, AMU contributor Greg Wittbecker explains.

After a year marked by tariff retaliation, price volatility and data center expansion, it is worth stepping back to assess where the building and construction end market stands heading into 2026.

For 2026, Pittsburgh-based Alcoa expects aluminum supply disruptions to continue offsetting anticipated smelter growth in Asia outside of China. China is described as nearing its smelter capacity cap, with limited room for additional supply growth.

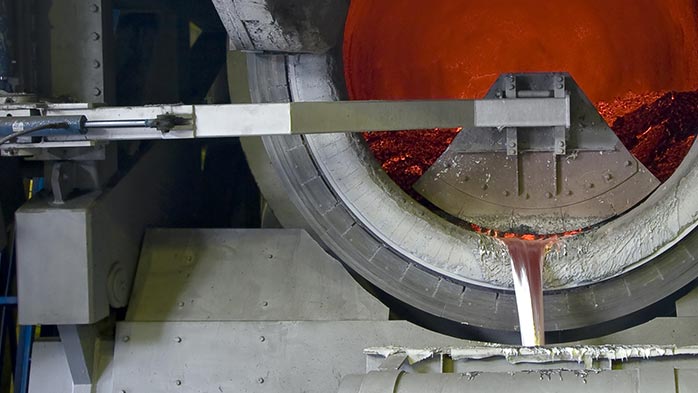

The first hot metal and commissioning for Rio Tinto’s low-carbon AP60 aluminum smelter in Saguenay, Quebec, Canada, is on track to be completed in the first quarter. The smelter is expected to be fully ramped up by end of the year, the mining company said in a production report.

Century Aluminum is taking a 40% stake in Emirates Global Aluminium’s (EGA) project to build the first primary smelter in the US since the 1980s. EGA will own 60% of the joint venture, which first proposed building the smelter in Inola, Okla., in 2025. The facility is expected to produce 750,000 tons of aluminum per year—an amount that would more than double current US capacity. That capacity total has been revised up from 600,000 tons per year.

Steel Dynamics Inc. leaned into its aluminum operations during its fourth quarter earnings call, touting progress at its flat-rolled mill in Columbus, Miss. – and hinting at future aluminum expansions.

“There’s absolutely no doubt that aluminum will be a growth platform for us going forward,” said Mark Millett, co-founder, chairman and CEO of the Fort Wayne, Ind.-based steel and aluminum maker. “There’s a lot of supply-demand dislocation, so there’s certainly phenomenal opportunities there for us.”

AMU’s January monthly survey results reveal expectations for the Midwest premium and used beverage can (UBC) scrap to remain largely stable in the month ahead, with a minority of respondents anticipating further upside. Recent response history and segmented recycler results further frame current scrap market conditions relative to responses from producers, manufacturers and traders. You can dig into the results here.

You can also see what the survey showed about lead times here. The devil is in the details.

Yes, LME prices are climbing, driven by factors such as China’s production cap being tested and strong prices for metals like copper, which supports substitution opportunities for aluminum, according to aluminum experts and AMU contributors Greg Wittbecker and Edward Meir. The two spoke on a wide range of topics during a recent Community Chat on Thursday, Jan. 22. It is definitely worth a watch.